IGAS-Hệ thống đo bồn tự động

Hệ thống giám sát Bồn từ xa IGAS-ATG là một giải pháp kết nối hệ thống đo bồn tự động, và mọi dữ liệu trong quá trình hoạt động sẽ được đưa về cơ sở dữ liệu trung tâm. Hệ thống IGAS-ATG cho phép :

- Giám sát từ xa lượng nhiên liệu ở trong bể chứa và bồn chứa.

- Báo cáo tự động về lượng nhiên liệu trong bể chứa theo thời gian cụ thể.

- Lưu giữ lịch sử các hoạt động bơm-nạp nhiên liệu ở bồn chứa ở cơ sở dữ liệu trung tâm.

- Quản lý biến động về nhiên liệu tại bồn chứa từ xa, do đó có thể phát hiện việc rò rỉ và gian lận nhiên liệu ( nếu có ).

- Kiểm soát tốt khi mức nhiên liệu ở cao hoặc xuống thấp trong bể chứa để đảm bảo việc bơm nhiên liệu ở mức độ cho phép.

- Trong các trường hợp khẩn cấp, hệ thống sẽ gửi các cảnh báo bằng văn bản hoặc email.

- Có thể kết nối được nhiều trạm khác nhau trên cùng một hệ thống giám sát từ xa. Hệ thống có sự phân cấp sử dụng và người quản lý của trạm nào chỉ có thể quản lý và xem xét được dữ liệu của trạm đó chứ không quản lý hay xem được các trạm khác.

Hệ thống giám sát từ xa IGAS-ATG cho phép kết nối trạm nhiên liệu của nhiều khách hàng khác nhau trên cùng máy chủ, mỗi khách hàng chỉ có thể quản lý hệ thống trạm nhiên liệu của mình mà không thể xem hay quản lý trạm nhiên liệu của khách hàng khác.

Hệ thống giám sát từ xa cho phép quản lý các hoạt động của nhân viên trong việc nhận lệnh và thực hiện lệnh bơm nhiên liệu ở các trạm của công ty.

Hệ thống giám sát từ xa IGAS-ATG làm việc tự động và độc lập khỏi sự kiểm soát của hệ thống POS và máy tính tiền. Hệ thống này có thể quản lý việc cung cấp và điều khiển trên các trạm nhiên liệu và kết hợp với các báo cáo kế toán. Hệ thống này cũng tránh và loại bỏ được những thao táo gian lận của nhân viên phục vụ ở các trạm nhiên liệu.

Khu vực áp dụng: trạm xăng dầu, kho chứa, bồn chứa và các doanh nghiệp công nghiệp.

CẤU TRÚC HỆ THỐNG

Để lắp đặt và cài đặt được hệ thống IGAS-TAG thì hệ thống bồn chứa, bể chứa phải được trang bị hệ thống que đo tự động ( hệ thống ATG ). Que đo bồn tự động của hầu hết các nhà sản xuất đều tích hợp được với hệ thống IGAS-ATG.

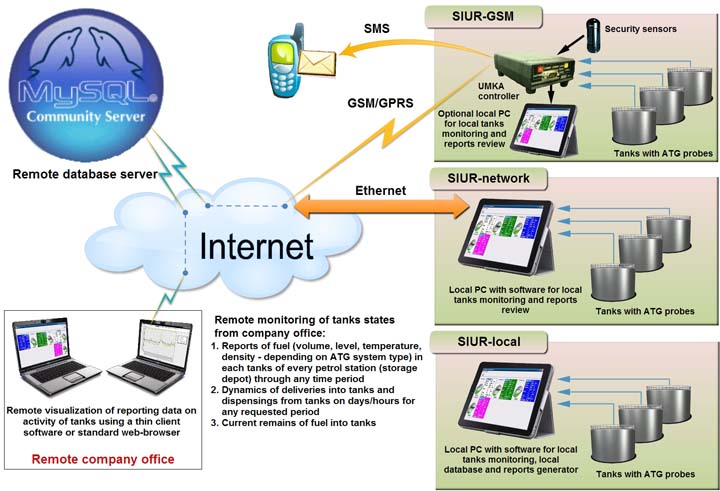

Sơ đồ kết nối:

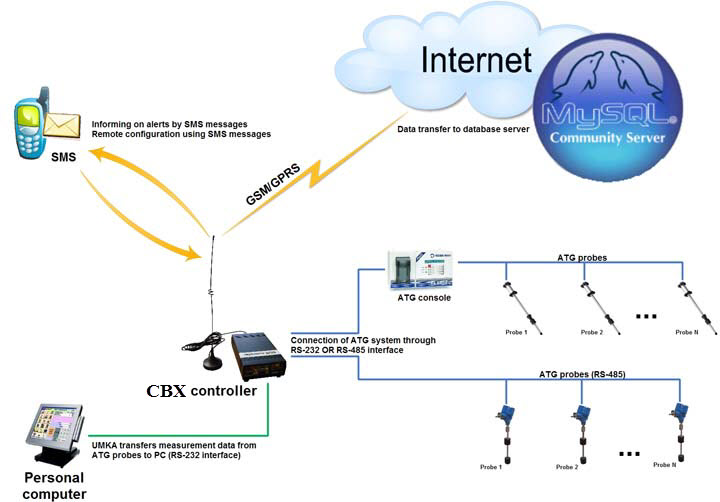

MODULE THU THẬP VÀ TRUYỀN DỮ LIỆU

Bộ điều khiển trung tâm CBX:

Trong quá trình hoạt động, bộ điều khiển CBX ghi nhận dữ liệu từ hệ thống que đo bồn tự động ATG và lưu ở trong bộ nhớ. Sử dụng thẻ Sim trong CBX sẽ cho phép kết nối và truyền các dữ liệu qua Internet thông qua GPRS và tới các máy chủ trung tâm. Trong các trường hợp báo động và khẩn cấp, bộ điều khiển CBX cũng có thể gửi các tin nhắn SMS để thông báo.

Tin nhắn SMS thông báo có thể được gửi theo các cách sau:

- Được gửi theo yêu cầu – Gọi đến một số quy định trước.

- Được gửi theo thời gian cố định được cài đặt trước ( ví dụ : Gửi hàng ngày vào buổi sáng lúc 10:00)

- Được gửi khi có 1 sự việc nào đó ( Ví dụ như khi nạp nhiên liệu vào thì hệ thống gửi thông báo tự động)

Sơ đồ kết nối

Trong trường hợp nếu các trạm nhiên liệu có kết nối với Internet thì có thể sử dụng giao thức kết nối qua Internet để truyền dữ liệu về trung tâm. Dưới đây là những lợi ích từ việc kết nối này:

- Không cần phải trả phí cho việc kết nối GPRS và lưu giữ dữ liệu.

- Không cần phải cài đặt thêm thiết bị bổ sung

- Có khả năng giám sát các bồn và xuất báo cáo trên PC

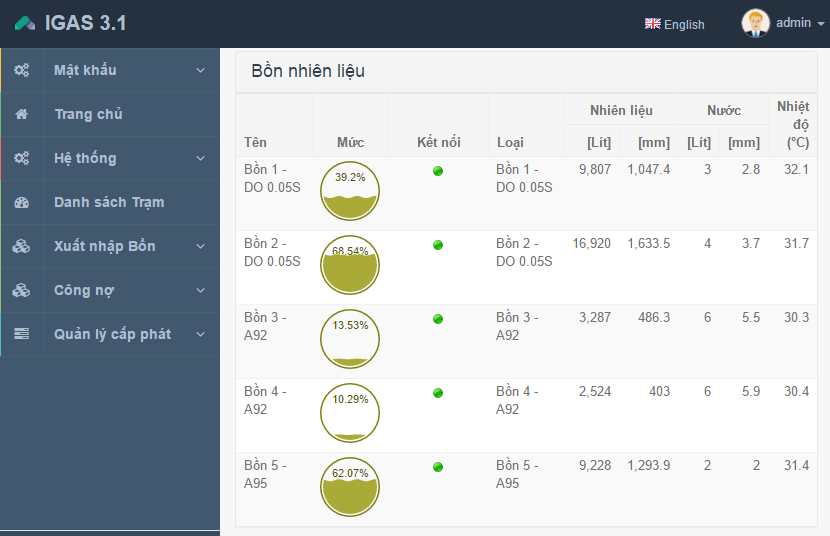

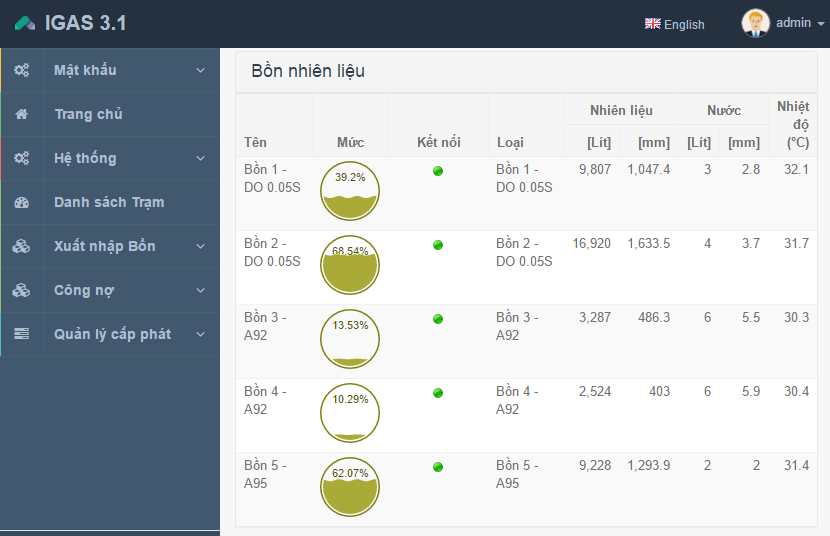

GIAO DIỆN HỆ THỐNG

CÁCH THỨC TRIỂN KHAI

Hệ thống giám sát từ xa IGAS-ATG có thể hoạt động trong 3 cấu hình sau:

- GSM/ GSM

- Network/ Qua mạng

- Local/Tại trạm

GSM:

- Cấu hình này của hệ thống giám sát từ xa dùng trong trường hợp cần thu thập dữ liệu từ các trạm bơm nhiên nhiệu không tập trung và thông tin dữ liệu của các trạm sẽ được lưu trong một cơ sở dữ liệu đặc biệt trên máy chủ ‘ sau đây gọi là : SERVER”. Giữa các trạm nhiên liệu không tập trung này không có dây kết nối giữa “Ethernet’ cũng không có kết nối “Internet”. Kênh GPRS không dây được cung cấp như là một giải pháp cho kênh truyền thông có dây. Để thực hiện việc này, một thiết bị phần cứng mang tên GSM-modem được cài đặt trên bộ điều khiển CBX. Các dữ liệu đo mức nhiên liệu bằng kênh GPRS sẽ được truyền tải qua Internet và đến máy chủ “server”, sau đó được lưu lại trong cơ sở dữ liệu của máy chủ. Và giờ đây, mỗi người dùng được cấp tài khoản có tên và mật khẩu truy cập, sau đó đăng nhập vào máy chủ thông qua Internet và nhận được các thông báo cũng như xem xét và quản lý các thông số về mức nhiên liệu, và cũng có thể xuất các báo cáo ở các trạm cho bất kỳ khoảng thời gian nào, tùy theo quyền được đăng nhập của mỗi loại tài khoản.

- Ngoài ra, phiên bản này còn được sử dụng mà không cần kết nối đến máy chủ. Trong trường hợp này, bộ điều khiển CBX có thể được sử dụng như một hệ thống giám sát trạm bơm mà người dùng có thể cài đặt cấu hình cho các thông báo bằng tin nhắn đến số điện thoại cụ thể. Những thông báo này có thể bao gồm những thông tin về mức nhiên liệu hiện tại có trong bồn, các thông tin về việc nhập nhiên liệu, xuất nhiên liệu, các thông tin cảnh báo về mất điện……..Các tin nhắn thông báo này cũng có thể được gửi dựa trên 1 sự kiện nào đó ví dụ như kịch hoạt các cảm biến anh toàn hay được gửi vào một khoảng thời gian cố định được cài đặt sẵn.

Network:/ Qua mạng

Cấu hình này của hệ thống giám sát trạm nhiên liệu từ xa được áp dụng khi cần thu thập dữ liệu từ một số trạm không tập trung cách xa về địa lý và các dữ liệu này cần được lưu giữ trong một cơ sở dữ liệu chung. Các dữ liệu thu được từ hệ thống que đo bồn tự động ATG sẽ được chuyển đến máy chủ trung tâm thông qua Internet và sẽ được lưu ở đó. Bất kỳ người dùng nào đều có thể truy cập vào máy chủ bằng cách đăng nhập theo tài khoản đã được cấp ( tên và mật khẩu). Trên giao diện của hệ thống có thể nhận được các thông tin hiện tại ở các trạm nhiên liệu cũng như xuất được các báo cáo phù hợp theo thời gian, tùy theo quyền đăng nhập được thiết lập từ trước.

Local:/ Tại trạm

Cấu hình này của hệ thống giám sát từ xa được áp dụng khi cần để cung cấp cho nhân viên phục vụ/quản lý tại trạm những thông tin về các thông số đo được ở bồn chứa nhiên liệu, mà không cần phải thu thập nhiên liệu từ các trạm không tập trung khác. Dữ liệu từ hệ thống que đo bồn tự động ATG sẽ được lưu trữ trong một máy tính đặt tại trạm, có các thông tin về mức nhiên liệu hiện có trong bồn và cũng có thể xuất các báo cáo theo thời gian nhất định.